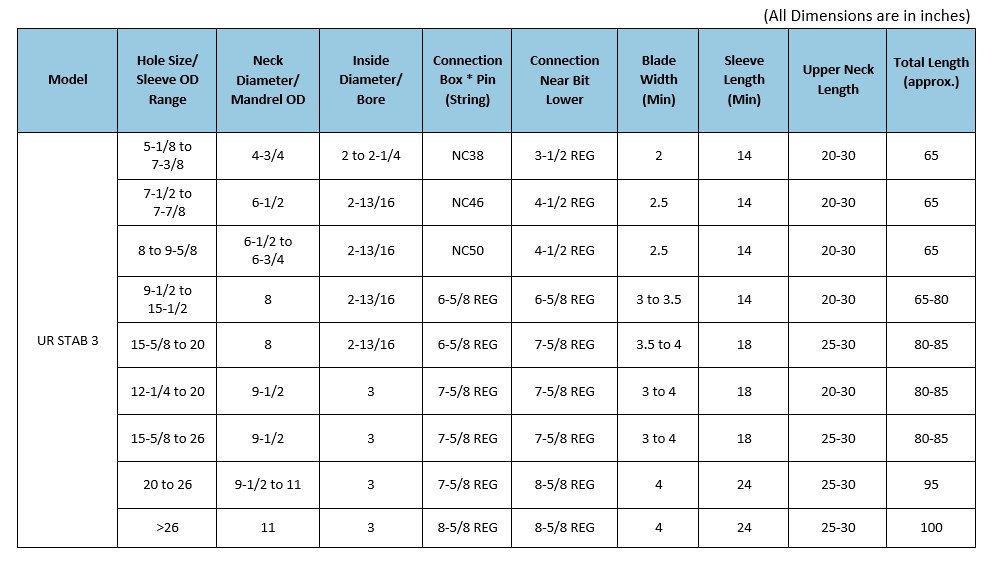

Replaceable sleeve stabilizers consist of replaceable sleeves that are mounted on the mandrel body. Consisting of a single mandrel and a replaceable sleeve, replaceable sleeve stabilizers are ideal in remote areas, where repairs and redressing of the blades are not feasible. The sleeve can be changed easily on the drill floor without the need for special tools. As an additional benefit, one mandrel can be used with sleeves of different sizes, reducing equipment costs. The crown surface and the leading edge of the sleeves are provided with protection against abrasion through hard facing. HF-2000, HF-3000, HF-4000 & HF-5000 types of hard facing can be provided based on customer requirements.The sleeve is screwed onto the middle threads on the outside of the mandrel and torqued up to the recommended value.

Mandrels are manufactured from AISI 4145H modified alloy steel fully heat treated (quenched and tempered) full length and sleeves are manufactured from EN-19 steel. The neck regions of mandrels have tensile properties and impact energy requirements equal to those of drill collars of the same size as specified in API 7-1 specification.

Integral blade stabilizer (IBS) is a one piece rotating stabilizer which can be placed near bit or up in the drill string. Integral blade stabilizers are cut out of a single piece of fully heat treated standard steel quenched and tempered full length.

Read More

UDT’s oilfield equipments and tools help minimize cost, maximize production, thus ensuring superior performance and delivering positive results every time.

The risk of unintentional sidetracking, vibrations & drill pipe whirl of bottom hole assembly

Explore

Drilling through rocky formations can lead to the caving of weak formations in a borehole.

Explore

Low reservoir pressure makes lifting of oil and gas from the earth to the surface difficult.

ExploreUDT downhole tools are used in a variety of formations to perform reaming operations during drilling.

Integral blade stabilizer (IBS) is a one piece rotating stabilizer which can be placed near bit or up in the drill.

Explore

Replaceable sleeve stabilizers consist of replaceable sleeves that are mounted on the mandrel body.

ExploreUDT gas lift equipment are used for effective gas lift operations in straight and deviated wells.

UDT wireline retrievable injection pressure operated gas lift valves uses nitrogen charged, multiply monel bellows to provide the force necessary to maintain the valve normally in closed position.

Explore

Orifice valves controls the volume of gas through the valve into the production conduit. These valves are used for continuous injection of gas. They are fitted mostly at the bottom of the wells.

Explore

Dummy valves are used to blank off communication between tubing and casing. In new installations, dummies can be retained in the mandrels until gas lift valves are required to.

Explore

UDT tubing retrievable injection pressure operated gas lift valves uses nitrogen charged, multi ply monel bellows to provide the force necessary to maintain the valve normally in closed position.

Explore

UDT conventional gas lift mandrels are equipped with external lugs to receive tubing-retrievable gas lift and orifice valve.External guards are attached to the outside diameter of the mandrels.

Explore

Side pocket mandrels are a part of tubing string. Side pocket mandrels features an oval body design and threaded connections for installation in the tubing string.

Explore

UDT offers a variety of wireline-retrievable latches for locking gas-lift valves, orifice valves and dummy valves into the appropriate side-pocket mandrel.

Explore

UDT running tools are used to install wireline retrievable gas lift valves, orifice valves and dummy valves into the side pocket mandrel pocket.

Explore

UDT pulling tools are used to retrieve wireline retrievable gas lift valves, orifice valves and dummy valves from the side pocket mandrel pocket.

Explore

UDT kickover tools are used to insert & retrieve wireline retrievable gas lift valves, orifice valves and dummy valves from the side pocket mandrel pocket.

Explore

UDT tubing retrievable reverse flow check valves are attached to the bottom of tubing retrievable gas lift valves that do not have an integral check valve to prevent.

ExploreUDT wireline winch units are used in both offshore and onshore areas and can be used for production and reservoir operations.

UDT make Skid mounted one or two piece wireline unit comprising power pack module with 84-125hp diesel engine and winch unit. This is compact...Read More.

Explore

UDT make Skid mounted one or two piece wireline unit comprising power pack module with 84-125 hp diesel engine and winch unit. This is compact.Read More

Explore

UDT make Truckline unit is a truck mounted wireline winch unit consisting of reel skid and power skid suitably mounted on right hand 6x4 drive.Read More...

Explore

Land line winch consists of Reel Skid (includes Drum compartment and operator cabin) and crane mounted on the rear of truck chassis delivering.Read More..

Explore

This is a Skid/trailer mounted, self contained, steel skid base structure, single drum wireline unit designed to provide....Read More.

Explore

This is a skid mounted, self contained, steel skid base structure, single drum wireline unit designed to provide a light weight, compact winch....Read More.

ExploreUDT range of connectors are suitable for a wide array of applications such as Drilling, Driving (Piling), Drill & Drive, Jetting, Offshore Jack-up, Offshore Subsea, Slot Recovery, Drilling with Casing and more.

UDT-Leopard is a high strength connector which has been used in many different applications.

Explore

UDT Swift is a heavy duty connection offering gas tight, metal to metal seal for gas wells.

Explore

UDT Lynx is a weight set connector. Non Rotational with no tooling & connection is fully

Explore

The Puma is a flush-threaded connector for use on exploration and platform drilling operations .

Explore